Our Tradition of Imagination

The knife is perhaps the most timeless tool of humanity. When you hold a good hand made knife you are not just holding a tool or an interesting keepsake; you are holding a legacy of the human race. You hold the patriot spirit of freedom; the pioneer spirit of determination, and the warrior spirit of Valhalla!

When you MAKE a knife, you are recognizing and honoring our human heritage. You are carrying on the traditions of makers past, and joining the ranks of those who saw what did not exist, and who were willing to risk and put in the effort to turn their vision into reality.

When you GIVE a knife you have made, you are passing on these traditions in the form of a treasured heirloom and future artifact. You are honoring the recipient with the effort of your time, skill and thoughtfulness; you are giving a piece of yourself.

When you TEACH someone to make their own knife, you help forge another link in humanity's legacy of makers. This is why I make knives and why I teach others how to "Make it like you mean it!"

The Maker's Way

I retired from law enforcement after 34 years of service and began my knife making journey at the age of 60. It's a wonderful time to be alive and information is easily accessible. I Joined the American Bladesmithing Association (ABS) and took their Introduction to Bladesmithing course at Texarkana College taught by Mastersmiths Jim Crowell and Mike Williams. I took several classes with ABS Matersmith Jason Knight, who has become a mentor and friend. I took a mosaic Damascus class with Mastersmith Ray Rybar, and online courses with Mastersmith Kyle Royer. I took a two week mosaic Damascus class with Salem Straub at the Center for Metal Arts in Pennsylvania, and most recently a class with Mastersmith Lin Rhea at his home shop in Arkansas. I continually learn from the community of makers who share what they are doing on social media.

Some guys retire and buy a Harley or a motorhome, I bought a power hammer, hydraulic press and heat treat oven. Bladesmithing is cheaper than therapy and the community of makers is packed with solid people who learn, create, do and share and encourage. That is the maker's way!

Make It Like You Mean It!

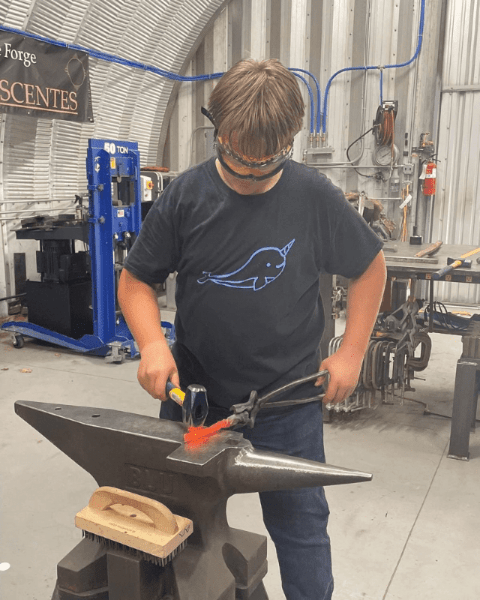

Bladesmithing Classes at Full Circle Forge, Leona Valley, California. I was involved in some aspect of training most of my law enforcement career. I instructed the use of firearms and chemical agents, first-aid, use of force, less lethal weapon systems, leadership, civil disturbance management, search and rescue, and mounted enforcement. It's just natural that teaching others is a part of my blade smithing journey. I learn best with the mindset of, "I will need to teach this some day." I was a beginner very recently, so what I have learned and how I learned it is very fresh in my mind. I spent enough money and dedicated myself to such an intense period of study and practice, that I could have had a Master's degree in just about any other subject and now I get to share the journey with others. Just one of the reasons I call my shop, Full Circle Forge and why the shop motto is Semper Discentes, which is Latin for Always Learning.

Intro to Bladesmithing

Begin at the Beginning

1 Day Class $225

Learn the basics of knife design, forging and heat treating. You'll use a hammer, tongs and anvil to forge a knife. You'll heat, quench and temper your blade, then use a belt grinder to shape and finish it. Includes exposure to the use of a hydraulic press and power hammer.

Must be at least 12 years old

Making Damascus

Learn how the magic happens

1 Day Class $400

We forge Damascus steel from various materials in various patterns, such as ladder, twist and feather. Students learn the principles of pattern welded steel and use of the hydraulic press and power hammer. Each student will leave with a billet of steel they forged to use as they wish. Includes materials. Note: we do not make mosaic Damascus in this class.

Make a Tomahawk

Forge a Throwing Tomahawk

1 Day $350

Feed your inner warrior and make a weapon Mel Gibson would be proud to own! Forged from a farrier rasp, these bad boys are beautiful. Includes materials.

Next Level Knife Making

Make It Like You Mean It!

3 Days $700Make a knife to be proud of. Make a knife that will impress your friends and family. Make a knife that will shave hair! Make it like you mean it! In this class students forge a full tang knife, learn and apply the principles of heat treating, affix and shape their handle and sharpen the knife's edge. Photo shows two students' knives on top and mine on the bottom. Students who have previously taken the Making Damascus class can use their steel to make their knife in this class.

NOVEMBER 2024 (FULL)

Make a Sheath

1 Day $200

Learn to make a leather sheath to fit your knife. Use stamping tools to create a unique design. Includes materials.

Exploiting the Nature of Steel

Steel does not want to be a knife. It has to be heated, hammered and forced into its potential. It becomes a knife kicking and screaming.

I make the best knives I can from high carbon steel or Damascus steel I forge in my shop. I heat treat the steel myself in a digitally controlled oven and test each blade with a calibrated hardness tester. I select the handle material to compliment the pattern of the steel and style of the knife. I carve, shape and polish the handle into its own expression of artful utility. If the use of the knife requires a sheath I make it myself from quality leather. It is the process of making which I enjoy. The process determines the quality of the finished product. Quality is the goal and it is important to me to control as much of the process as I can. As my knowledge and skill increase, so does the quality of my knives. This is another reason I teach, because I learn when I help others learn.

Shop Now

For Classes and Available Knives

Intro to Bladesmithing, SEPTEMBER 24, 2022

$225.00

One Day class learning to forge a knife from a railroad spikeQuantityComing soon

Damascus Class OCTOBER 22, 2022 (FULL)

$400.00

Forge a billet of Damascus in Ladder, Feather or Twist patternQuantityAll options are out of stockComing soon

MAY 13, 2022 Tomahawk Class (FULL)

$400.00

Forge a tomahawk from a farrier raspQuantityAll options are out of stockComing soon

Viper, EDC Knife

$350.00

Full Tang 1084 high carbon steel blade with burlap micarta handle scales. Includes horizontal carry cross draw sheath.

SOLDQuantityAll options are out of stockComing soon

8 Inch Damascus Chef Knife

$750.00

Low Layer twist pattern of 1084 and 15N20 High Carbon Steel. Hand forged to shape. Full tang.

SOLDQuantityAll options are out of stockComing soonFAQs

How should I care for my carbon steel knife?

What do I need to bring to a class?

Where are the classes held and what are the hours?

Can I order a knife from you?

How long does it take you to make a knife?

Do you do custom knives?

Are you ever going to go on "Forged in Fire"?

What steel do you use in your knives?

Gallery

Photos & videos of my adventures in iron

Click on photos to expand

Social Feed

follow me on Instagram @dave_sauer_knives

Email:

dave@

© 2022